What are the Key Prerequisites to HVAC Qualification?

What should happen before one gives a green signal for HVAC qualification to begin? Why is this question important? For three reasons:

- At a very basic level, you don’t want the qualification to fail. If a system has not been thoroughly tested during commissioning, it’s an invitation to failure during qualification.

- You don’t want to qualify a system that is still undergoing commissioning or adjustments of any type. If someone tweaks a system setting or adjusts a damper during the qualification, such a qualification has no validity.

- Finally, you don’t want to rest your qualification on data that is not valid. That’s why instrument calibrations and the qualification of a system monitoring critical parameters are important prerequisites.

Defining and satisfying correct prerequires save us from the above risks.

Prerequisites: Three groups

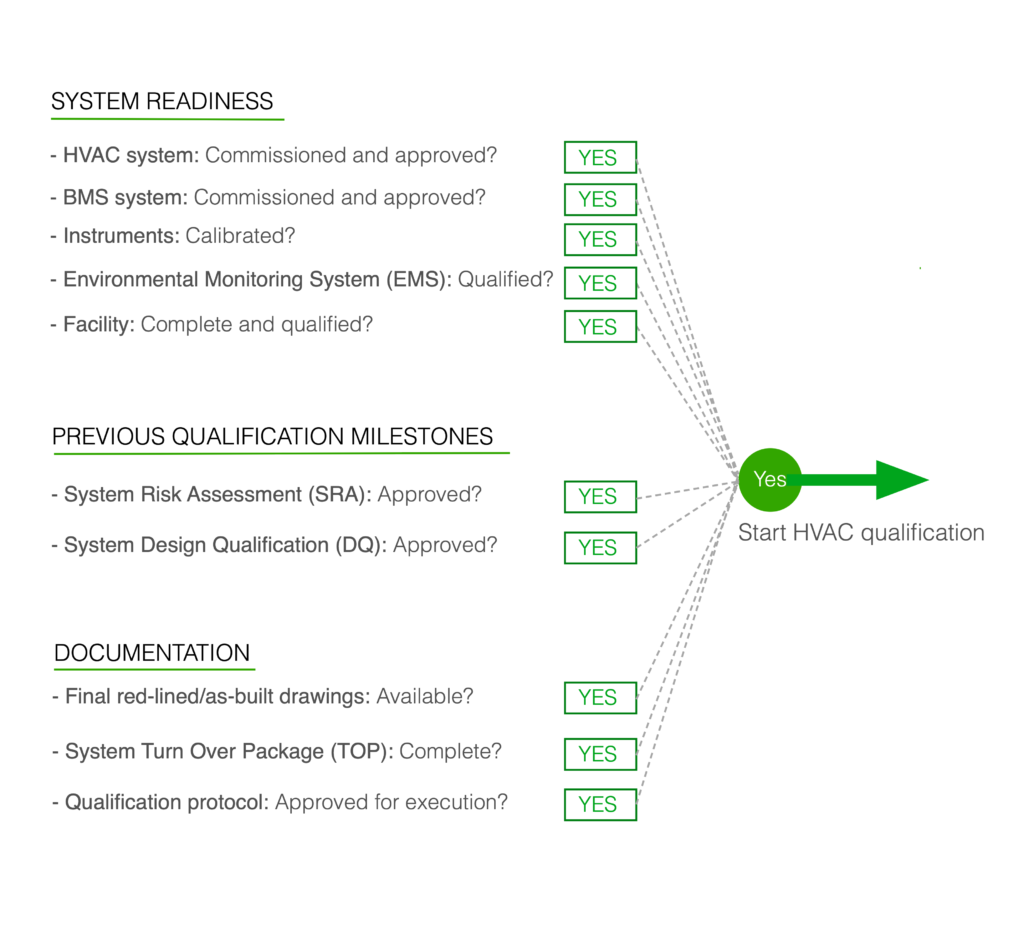

Instead of seeing prerequisites as a series of disparate requirements, one can group them under three headings:

- System readiness: These prerequisites ensure that HVAC systems are physically and operationally ready to be qualified. Going a bit granular, “system readiness” practically means:

- HVAC system is successfully commissioned, tested and approved.

- Building Management System (BMS) system that controls the HVAC systems is also tested and approved.

- All instruments are calibrated.

- EMS system that monitors the critical parameters (temperature, relative humidity and rooms pressures) is qualified.

- The facility (rooms, architectural finishes, materials, etc.) is complete, and GMP areas are qualified.

- Previous qualification milestones: This step ensures we are not jumping to the qualification without prior assessments and design checks. At minimum:

- System Risk Assessment (SRA) is approved.

- System Design Qualification (DQ) is approved.

- Documentation: This part ensures that required documentation (IOQ protocol) is in place to support qualification. In addition, some projects require the System Turn Over Package (all documents related to HVAC systems–drawings, data sheets, catalogs, spare parts list, etc.) to be complete.

The diagram below captures it all.

Typically, under the pressure of the project schedule, people often question whether all these prerequisites are really required. Can we not proceed with HVAC qualification while some of these are not yet done? My experience is that’s a slippery path to even more delays and complications.

Of all these prerequisites, the most important is the completion and approval of HVAC commissioning. If commissioning is not done properly or is incomplete, one should not start HVAC qualification. That’s a proven recipe for a mess. Similarly, EMS qualification is important to ensure all the critical test data (temperature, humidity, pressure) come from a qualified system. Facility completion/qualification is also important because the finishes and materials of walls, doors, etc., can also affect the parameters like particle counts or air distribution.

Working diligently to satisfy correct prerequisites is a sure way to get all these items out of the way and deliver successful HVAC qualification. Leaving you with…

Point to ponder: Which of the two comes first: Approval of BMS commissioning or HVAC commissioning?