How to Commission HVAC Systems for a Biopharma Facility?

HVAC commissioning is often an overlooked activity in biopharma projects. In project schedules, it is either completely ignored or grossly underestimated. Some people think it is all about air balancing–and nothing more. In many projects, once the construction is over, people start pushing hard for qualification and handover without realizing that is not possible without successful commissioning.

But those with experience know commissioning is a complex, time-consuming and unpredictable activity. Complex because it means making different parts of an HVAC system—AHUs, fans, ducting, piping, electrical, BMS & EMS, CAVs/VAVs—to work together seamlessly even though these have been supplied/constructed by different vendors with different agendas. Time-consuming because it’s a highly manual and iterative activity. And finally, you can’t beat its unpredictable nature. All kinds of issues crop up, from inadequate design to underperforming equipment to loose/wrong duct connections, leaking coils, room leaks, control complications, contractual issues and more.

Unless planned and executed systematically, it morphs into a significant bottleneck. This post lays out a broad roadmap for HVAC commissioning from start to finish. The word “broad” is important because this is a deliberate attempt not to describe everything for the sake of simplicity.

Context

To provide a context for the story of HVAC commissioning, let’s first assume:

- You have a biopharma facility consisting of Grade C and D rooms that require specific air changes, pressure cascade, temperature and relative humidity.

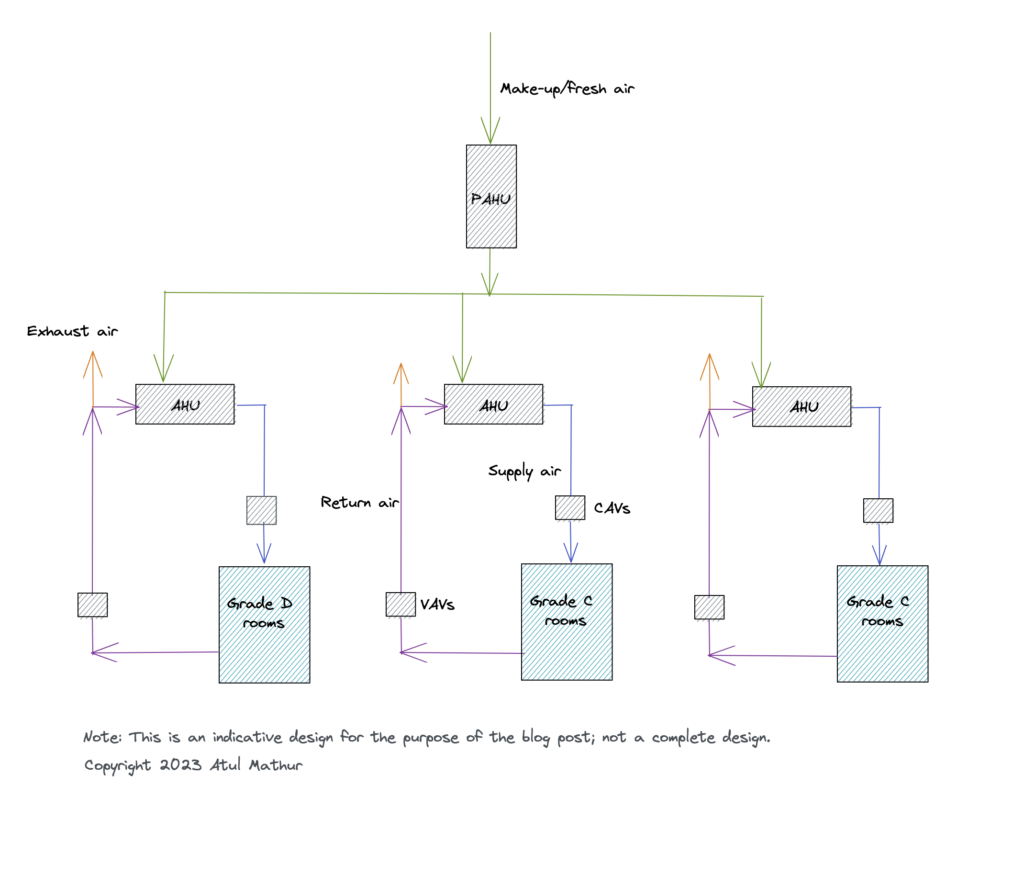

- Three secondary recirculation type Air Handling Units (AHUs) serve this facility with one Primary Air Handling Unit (PAHU) to treat the make-up/fresh air.

- Supply air to the rooms is controlled by mechanical CAVs (Constant Air Volume boxes) and return air by automated VAVs (Variable Air Volume boxes).

- A Building Management System (BMS) system controls the four HVAC systems, and an Environmental Monitoring System (EMS) monitors the critical room parameters (temperature, relative humidity and room differential pressures).

The following diagram provides a graphical representation of the system. (Again, this is not an attempt to describe the detailed design.)

With the above systems in mind, let’s talk about the roadmap for commissioning.

Commissioning: Five steps

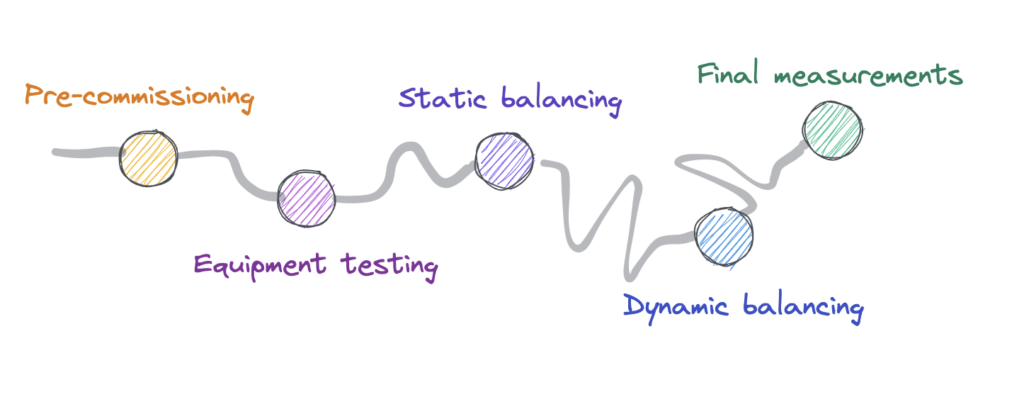

Broadly speaking, commissioning starts with pre-commissioning and ends with the final measurements.

The wavy path connecting the five steps indicates the bitter reality: It’s an activity with many twists and turns.

Pre-commissioning

Commissioning should start only after Mechanical Completion (MC), which means only after the installation (AHUs, piping, ducting, instruments, power, room-side grilles/diffusers) is complete. Pitfall No. 1 is trying to commission something that is not even constructed completely.

During pre-commissioning, the objective is not to test anything but to simply start the AHUs safely and slowly. Few basic checks before starting the AHUs:

- BMS and VFD: Software loaded?

- Rooms: No dusty works?

- Filters: Temporary filters installed both in AHUs and in rooms (return/exhaust grilles)

- Dampers: Manual dampers, CAVs, VAVs, fire dampers – all open?

If these basics are in place, start the AHUs (low speed initially) and check if the fans are rotating in the right direction, any abnormal vibrations or noise, coil leakage, drain pipe issues, unexpected tripping, motorized dampers not opening or closing, etc.

If pre-commissioning is fine, the next step is equipment testing.

Equipment testing

The purpose of equipment testing is to ensure that equipment can perform its duty without any problems.

For example, if an AHU is designed for 30,000 CMH, is it capable of delivering this much airflow? If you expect an off-coil temperature of 9 C at the PAHU, is the chilled water coil performing if you open the valves completely? Is the heating coil performing? Any air leakage or abnormal noise or vibrations or excessive current? The same goes for CAVs and VAVs (including their BMS interface): we need to test them upfront to ensure the required functionality.

If equipment testing goes well, it shows that the main equipment has the capacity to perform. But if things don’t go well, equipment testing will reveal problems like:

- AHUs

- Can’t deliver the required airflow or are operating at a very high speed

- Excessive leakage into/out of AHU doors/joints

- Coils are not performing

- Excessive noise or vibrations

- High current

- Condensate water is not draining properly

- CAV / VAV

- Stuck or not functioning at the required duty

- Motorized dampers & valves

- Actuators are not working

- Moving in the opposite direction

If the equipment testing goes well, the game shifts to static balancing.

Static balancing

The purpose of static balancing is to ensure all airflows—supply, return, fresh air and exhaust–are balanced to the design requirements. This activity involves adjusting dampers, CAVs, VAVs and measuring air flows in the main branches, key sub-branches and at all room-side diffusers/grilles. The usual tolerance is +/-10% of the target design air flows, but personally, I prefer +5 to +10% (of design) on the positive side.

If static balancing is done properly, the output is::

- AHU operating set point (static pressure in the main supply air duct, speed, current)

- Supply, return, fresh and exhaust airflows in all main branches and key sub-branches

- Airflows at each grille/diffuser

- Air changes in all classified areas (Grade C & D)

- Settings of all CAVs and manual dampers

You’ll note that during static balancing, room pressures don’t come into play. If static balancing goes well, that’s a good achievement, but the next challenge is even bigger.

Dynamic balancing

Once all four AHU systems are statically balanced, it’s time to go for dynamic balancing, where the objective is to achieve the design room pressures–and ensure the required pressure cascade. Dynamic balancing involves adjusting the room return or exhaust air flows to get the individual room pressures as per the design. It involves either manually adjusting dampers or CAVs or working with BMS team in case of automated VAVs.

Dynamic balancing is done with all doors in the facility closed.

If dynamic balancing goes well, the results should show that all individual room pressures are averaging around the target design values with fluctuations not more than +/- 3 Pa (ideal). For example, if a room is designed at 30 Pa, the actual pressure between 27 to 33 Pa is acceptable.

Achieving facility-wide room pressures is not easy because all kinds of issues crop up during this phase: Room leakages (ceiling, walls, penetrations), VAVs not performing or under or over-sized, doors either leaking too much or too little air, issues with pressure transmitters, etc.

Let’s say pressures are all okay. What else?

Along with the dynamic balancing, on a parallel track, one should keep monitoring all the key temperature and relative humidity parameters, specifically:

- Room temperatures and relative humidity

- AHU side temperatures (return air, off-coil, etc.)

If pressures, temperatures and humidity are okay, it’s time to shift gears to the last step.

Final trends and measurements

At this final stage, it’s time to capture the trends and do the measurements for the final commissioning records:

- Rooms

- Air changes

- Room pressures and room-to-room differential pressures (24-hour trends)

- Temperature and humidity trends (BMS, EMS and portable loggers)

- AHU (final operating data)

- Main supply, return, fresh air and exhaust airflows

- Pressure profile of AHU (drops across filters, coils, etc.)

- Fan speed, current and voltage

- All temperatures and humidity trends (off-coil, return air duct, supply air duct, etc.)

- Chilled and hot water flows

- Noise and vibrations

- BMS

- VAV % opening trends

- Temperature Control Valves (TCV) % opening trends

- AHU operations screenshots showing the set points and operating conditions

If everything goes well by now, one can proudly declare that HVAC commissioning is practically done.

Note: I have deliberately steered away from describing the BMS side of the story and a few other things. Even without that, it’s a long post.

Leaving you with…

Point to ponder: Why should room supply air flows/air changes be measured again during dynamic balancing even though these were measured during static balancing? What’s the risk if this is not done?

Excellent information and learnt the basics clearly. Thank you so much for posting