Step by Step, How to Qualify HVAC systems?

At which point an HVAC qualification team can proudly say, “HVAC qualification is done”? Is it after successfully completing Operational Qualification (OQ) or Environmental Monitoring Performance Qualification (EMPQ)? In my view, the right answer is EMPQ. Until EMPQ concludes, the game is not over!

But then, what’s the starting point? That’s easy: HVAC User Requirement Specifications.

This post takes you on a step-by-step journey of HVAC qualification by connecting the dots between the starting and end points—and briefly describing each step along the way.

HVAC qualification: The key steps

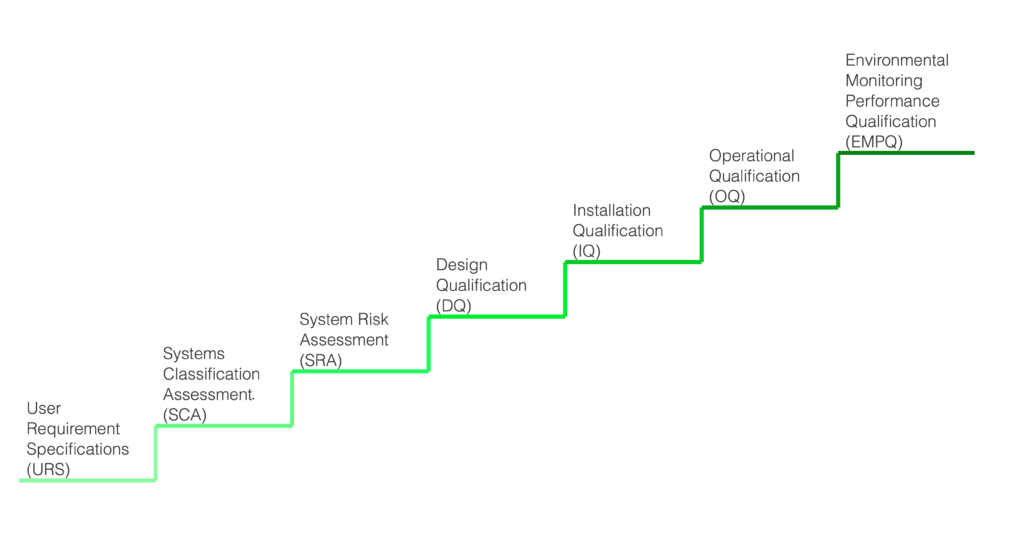

The diagram below shows the journey of HVAC qualification from User Requirement Specifications (URS) onwards until EMPQ.

Let’s look at each step in more detail without getting bogged down in too many details.

HVAC URS: What’s needed?

To set the ball rolling on HVAC qualification, the first step is HVAC URS, which defines all the HVAC requirements. One of the most consequential documents, URS answers the basic question: What is expected from the HVAC systems to ensure the facility is fit for the products, processes and people?

Depending on its nature, each requirement is labeled as Quality, Business or Environment, Health and Safety (EHS). HVAC qualification focuses on the Quality requirements, the ones that potentially affect product quality.

A typical HVAC URS includes:

- Room classifications (A, B, C & D)

- Room pressure requirements

- Temperature and humidity requirements

- Air changes

- Automation requirements (instrument, control, monitoring, alarms)

- Specific exhaust requirements

- AHU zoning

- Basic engineering requirements (Air Handling Units, fans, ducting, piping, etc.)

- EHS requirements

- Fire protection requirements (smoke detectors, fire dampers, etc.)

- Emergency power requirements (if applicable)

A clear and comprehensive URS is a great beginning for HVAC qualification.

Since URS applies to all HVAC systems, the next step is to figure out which systems really need to be qualified.

System Classification Assessment (SCA): DI systems?

Considering not all systems need to be qualified, a System Classification Assessment (SCA) is carried out to categorize the HVAC systems into two groups:

- Direct Impact (DI) systems

- Not Direct Impact (NDI) system?

All DI systems need to be commissioned and qualified, whereas all NDI systems need to be only commissioned.

SCA evaluates each HVAC system by asking a series of eight or nine questions to figure out whether a system is DI or NDI, but practically, any HVAC system that serves the main process areas (potentially impacting product quality) is a DI system. For example, a system serving the Compounding Room will be a DI system, whereas a system cooling the main utility building will not be.

To carry out SCA, the HVAC concept design should be ready so you know how many HVAC systems are involved in the whole facility and which specific areas these systems serve.

What‘s next?

System Risk Assessment (SRA): Key risks?

The ultimate job of a qualified HVAC system is to comply with all the quality requirements mentioned in the URS, from room classifications (particle counts) to room air changes to room pressures to temperature and humidity.

But what could go wrong that would prevent an HVAC system from delivering on those requirements?

The purpose of SRA is to figure out the risks associated with each HVAC system—and identify the ways to mitigate them. The mitigation measures could be related to design, testing and procedural controls.

For example, if URS requires Grade C classification for a certain area, the associated risks could point to the following measures:

- Design: Provide terminal HEPA filters, a certain minimum number of air changes and low wall return intakes

- Testing: Factory filter leak test certificates, field installation checks and on-site filter leak testing, air balancing and testing of air changes, non-viable particle count tests

- Procedure: Site procedure to include periodic testing of terminal filters and air changes

Done properly, SRA identifies all possible risks for the qualified systems and points to specific mitigation strategies to keep the risk as low as possible.

What’s next?

Design Qualification (DQ): Is design okay?

Post SRA, the attention shifts to the HVAC design to review whether it aligns with the URS and SRA. For DQ, the following detailed design drawings and documents should be available:

- GMP classification drawings

- AHU zoning drawings

- Pressure cascade layout

- AFIDs (Air Flow Instrumentation Diagrams)

- Instruments layout

- HVAC specifications

- Automation Functional Descriptions

- Catalogs, datasheets and equipment schedules

To pass the DQ, all quality-related URS items and SRA’s mitigation strategies should be verified in the above documents. For example, if SRA points to terminal HEPA filters, it should be verified on the drawings, and the specifications should state the right efficiency of the filters along with factory test certificates.

In my experience, many problems that arise during the commissioning can be traced back to design. Clearing the DQ is a major milestone.

What’s next?

Installation qualification (IQ): Installed as intended?

The purpose of installation Qualification (IQ) is simple: Whatever is shown in the design, verify that it is installed the way it should be.

IQ involves verifying the availability of the latest HVAC design drawings and documents, walking down the system and verifying the installation. In particular, IQ requires verification of quality-related items like HEPA filters (installation checks and verification of factory test certificates) and critical instrument checks (installation checks and calibrations).

If IQ passes, it assures the system is installed as intended in the design.

The next step is to do functional checks.

Operational Qualification: Final results?

Successful commissioning is a prerequisite to HVAC OQ, which involves a series of tests to verify that a DI HVAC system satisfies the quality requirements in the HVAC URS. Practically, it boils down to passing the following tests:

- HEPA filter leak test

- Room air changes

- Unidirectional Airflow (UDAF) filter face velocity

- Room non-viable particle counts test

- Room pressure

- Room differential pressure

- Airflow visualization test

- Room temperature

- Room humidity

Clearing OQ is a huge milestone, but the game is not yet over.

Environmental Monitoring Performance Qualification (EMPQ): Performance during normal operations?

In this final step–EMPQ–the system is tested while simulating normal operations. Users would run some processes and move around the facility just like normal operations, and all the while, the following key parameters are monitored for compliance with the URS requirements:

- Viable particle counts

- Non-viable particle counts

- Room differential pressures

- Temperature and relative humidity

Once PQ passes, the system is ready for operations.

Note: I have purposefully left out things like Validation Master Plan, Design Review (DR), Traceability Matrix and Qualification Summary Report…all in the interest of not complicating the story.

Finally, leaving you with…

Point to ponder: Most C&Q projects start with a classic stumbling block…clients/users can’t provide a proper URS to begin with. Should C&Q team help clients produce URS even though it is not their scope? Is a smart move?