How to Avoid Extra Cost, Delays and Confusion by One Simple Step: Writing User Requirements at the Very Beginning

A few years back, as the owner’s HVAC Lead in a biopharma project, I had an urgent task on my hand: Create User Requirements Specifications (URS) for the Primary Air Handling Units (PAHUs). Unfortunately, this particular URS never saw the light of the day.

Since PAHUs are not particularly complex equipment, it should have been a straightforward affair to produce a decent URS, but there was a big catch involved.

The PAHUs for which I was to urgently produce the URS had already been bought a year back, well before I joined the project. You got it right: It was a URS in retrospect.

While writing the URS, I tried to do what was logical: Check the alignment between what I was writing in the draft URS and the technical data of those existing PAHUs. And that’s where came a difficult fork in the road.

If I strictly followed the company guidelines for the URS, the existing PAHUs would fail to comply. And if I try to “adjust” the URS to suit the PAHUs, then I was deviating from the company guidelines. (Examples: Company guidelines required a minimum of 600 mm wide service doors, but the existing PAHUs had only 400 mm wide doors. The same was the case with the insulation used in the sandwich panels and also with some design parameters.)

Finally, the URS was completed in all respects but never issued. The team realized that it was a mistake to buy those PAHUs without a URS one year back, and it would only compound the problem if we either issued a URS that failed the equipment (which can’t be returned) or manipulated URS to pass it.

This was a classic case of buying capital equipment without preparing a URS beforehand. Unfortunately, this is not uncommon.

It’s a routine affair in multimillion-dollar projects to not create URS at the beginning and still move forward to buy critical and expensive equipment and go ahead with the design. Rare are those projects where URS is prepared right at the beginning of the project when it is needed most.

That brings us to the following four questions:

- Why do the project teams underestimate the value of URS?

- Why is it so difficult to prepare a URS that it often gets delayed or completely ignored?

- What’s the path forward if a proper URS needs to be prepared?

- What should go into an HVAC URS?

URS: Why underestimate the value?

What happens when a project moves forward without a URS?

Equipment is bought that doesn’t fully comply with the owner’s guidelines and standards. The design team makes a number of assumptions that might not be right. Design goes through multiple cycles of reviews and confusion, leading to lots of rework. Many times, during construction, installed walls or equipment get demolished and reconstructed. New items are added to the scope much later in the project when the cost of the addition is much higher than at the beginning. Qualification work is completely stalled for the lack of a URS. Worst, the functioning systems do not perform as required.

In short, the damage is widespread, and who pays for all the extra costs and delays? Owners themselves! So why can’t people see the value of URS?

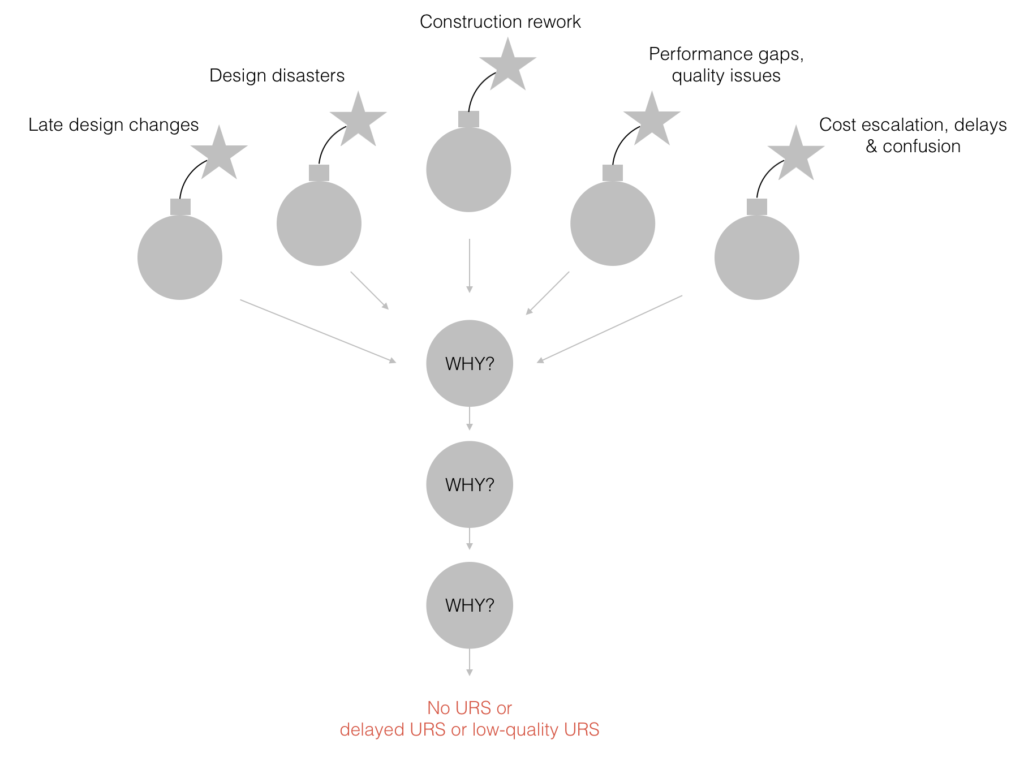

The reason is simple: Not asking “why?” Every time design changes or some construction rework happens or systems do not perform, the focus is on fixing the problem—and not asking “Why this problem came in the first place?”

Unless you’re a very observant person who keeps asking “Why? Why” Why?” you won’t realize that many problems could have been avoided by simply writing down—in black and white—detailed requirements at the very beginning of the project.

This basic inability to connect the dots backward is the reason why most people think URS is just another document—and not a top priority item. Underestimating the value of a URS and not investing enough effort to get it done upfront is the first symptom of dysfunctional project management.

I have attended many risk management meetings in projects where people talk about all kinds of risks, except the one on which they keep sitting: No URS. This is a tragic paradox.

Why is it difficult to prepare a URS?

Is preparing a URS about technical understanding or writing abilities or both? Actually, it is both plus much more.

Ideally, the person writing a URS requires abilities in the following areas:

- Knowledge: Technical depth and breadth in the subject (HVAC, process, architectural, etc.).

- Technical writing: Ability to describe technical stuff in a clear and concise way.

- Research: Ability to absorb and discern large amounts of technical information (guidelines, standards, regulations, information from previous projects, design brief/concept reports).

- Collaboration: URS can’t be written in isolation; the person leading the effort should be able to deal with all kinds of people who have different agendas and understanding of the subject.

- Attitude to get it right: The person writing the URS should understand that even one wrong sentence can lead to tremendous confusion, cost and delays later in the project.

But guess what? None of the above abilities are of any importance unless someone has the discipline to avoid all the juicy distractions (meetings, emails, trial discussions, etc.)—and sit down in a chair to focus and write it down.

Overall, the lack of prioritizing the URS and the inability to focus are two big reasons why the poor URS keeps getting kicked down the road as long as it is possible.

In my opinion, either the engineering design company or the C&Q team should offer support for preparing the URS if they find that owners can’t get it done. By helping the owners put their requirements in black and white, you help yourself in a big way. Owners still own the URS but helping them create it is a smart way to get over this hurdle.

Cooking up a URS

Here is a simple 4-step process to cook up a URS:

Marinate

The biggest barrier is: Where to start? So the very first goal should be not to write anything but gather the following inputs and “marinate” your mind with the right information:

- Format: Figure out the right format (typically, there will be some SOP specifying this).

- Old URS: URS from any similar project within the same organization. Decent precedence makes life easier.

- Company guidelines and standards: Go through the relevant in-house stuff.

- Design inputs: Concept design report.

- Stakeholders: Identify the key stakeholders who will review and approve the URS

Cook

Once marination is done, it’s time to simply sit and write it down. (Here, my technique is to simply set up a timer on my phone for 45 min. and start writing without any interruptions About 4-7 such 45-minute sessions spread over 4-5 days are enough to get the first draft ready.

Taste

Once the draft is ready, let it be tasted by the stakeholders. Let them review and provide their comments. This is a circular activity. 4-5 rounds of comments, reviews and revisions are common. So be patient, always remembering that going in circles is an integral part of the whole process.

Serve

Once done, get it approved and issue it to all relevant team members: Contractors, vendors, own team, etc. Everyone should know about it.

Finally, let’s talk about HVAC URS.

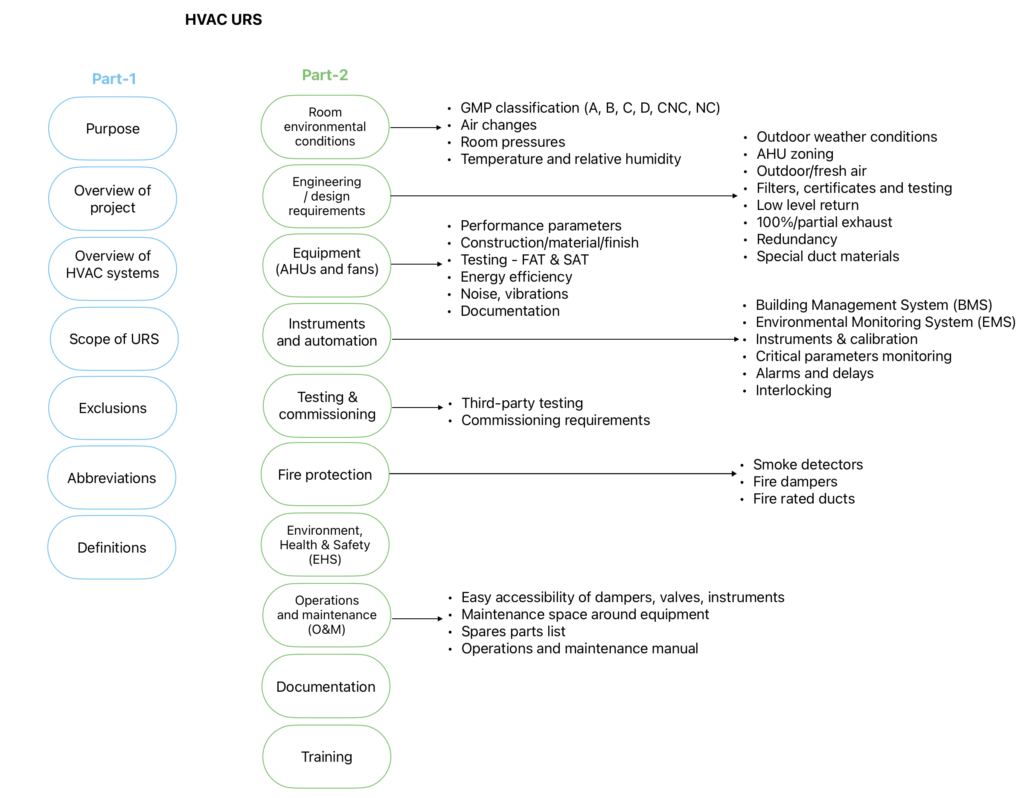

What goes into HVAC URS?

Of course, different projects have different requirements, formats, etc., but the diagram below shows a general structure and some of the contents of a typical HVAC URS for a biopharma project. It’s just a sample.

Finally, how long does it take to create a URS? Usually, 1-2 weeks to write the first draft, but 4-6 weeks to navigate the review process. Not that it should take that long, but that’s the reality.

If you ever get an opportunity to write a URS, grab it with both hands: It’s a huge contribution to both your own knowledge and the project itself.

Leaving you with a point to ponder…

Should URS be prepared only for the direct impact systems or for all systems including the so-called black systems like chilled water, chillers, hot water, fire protection, etc.?