How to Set Alarm Delays for GMP Differential Pressure Alarms

Among all the HVAC-related GMP requirements, one of the most critical is the pressure difference between rooms of different grades. According to Annex-1 (EU GMP), a minimum of 10 Pa pressure difference should be maintained between rooms of different grades.

The regulations also require a system of alarms to warn the operators in case the differential pressures collapse (for example, due to a failure of air supply). This is all straightforward–most facilities follow it. But then comes a difficult turn.

Annex-1 goes on to mention that any alarm delays should be assessed and justified. This is where things get complicated.

Setting alarm delays for the differential pressure alarms is not a difficult task. It’s a matter of a few clicks on a laptop. But assessing and justifying the delays is not easy, as you’ll see shortly. It requires simulating people and material movement, a careful study of pressure fluctuations and recovery, and writing an engineering report.

This post lays out a pathway for assessing and justifying differential pressure alarm delays for a biopharma facility.

Why the alarm delays matter

Before we figure out how to assess the delays, let’s step back and reconnect with the three reasons why these delays are critical for a facility.

- Annex-1: First, as mentioned above, it’s an Annex-1 requirement. You just can’t set delays arbitrarily without a proper justification. [Many existing facilities suffer from this gap: The delays were set in the past, but today they lack a justification to support those delays.]

- Nuisance: Second, optimizing the delays is important to ensure smooth operations. If you set very tight delays, it could lead to nuisance alarms whenever facility doors are opened/closed. But if you set very relaxed delays, it creates the risk of cross-contamination.

- Critical change: Finally, once the delays are set, and production starts, it’s not possible to tweak the delays without going through a painful change control process.

Overall, it’s prudent to properly assess, justify, and set the differential pressure alarm delays at the very beginning—and not kick the can down the road.

That brings us to the last element of this post: How to assess and justify the alarm delays?

Assessing alarm delays

Broadly, the whole exercise can be divided into four neat steps:

- Check the prerequisites

- Simulate people and material movement

- Study differential pressure fluctuations and recoveries

- Write a report

The procedure described here is in the context of new projects. For existing facilities that are already in operation, skip step 2.

Step 1: Check the prerequisites

Check the following prerequisites before embarking on this exercise:

- HVAC: The HVAC system is fully commissioned and approved. [With all doors closed, all room pressures should be stable without any alarms.]

- Automation: The Building Management System (BMS) and Environmental Monitoring System (EMS) are fully commissioned and approved. [BMS should be operating normally and controlling room pressures. And EMS should be functional to capture, display, and record room pressure trends.]

- Facility: The facility (doors, walls, ceilings, etc.) is fully completed.

Once the basic prerequisites are in place, it’s time for action on the field.

Step 2: Simulate people and material movement

The purpose of this step is to simulate people and material movement throughout the facility as it would be during normal operations. The key here is to prepare first and then act.

Prepare

- Engage two experienced operators who understand the people and material movement across the facility.

- Provide them with the approved drawings: Facility layout, people, and material movement layouts.

- Discuss the scope of the activity and how they should move around the facility and record the door opening/closing timings.

- Provide a trolley to simulate material movement.

- Provide a digital clock to help capture the door opening/closing timings (assuming these timings are not available on BMS).

- Provide them access to the whole facility.

Move

If the preparation is right, the next step is simple: Move around the facility by opening and closing the doors. Go with the trolley wherever material movement is needed (for example, to enter/exit Material Air Locks).

As one person simulates the movement, the other should note down the timing of each door opening/closing. This data will be critical when analyzing differential pressure trends.

This whole exercise is better done after normal working hours when no other personnel are moving around the facility.

Step 3: Study differential pressure fluctuations

Of all the steps, this is the most painstaking: One needs to sit down in front of the EMS monitor and carefully study each differential pressure trend in the context of door openings and closings. It’s easy to get lost in the fog of trends and data unless one has the clarity on what to look for.

What to look for?

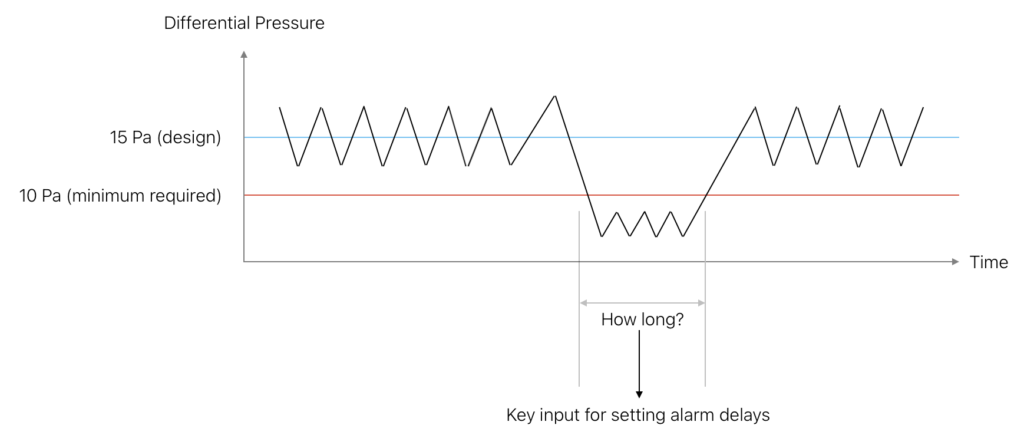

For each trend, zoom into the window of related door opening/closing timings and see: Did the differential pressure (DP) drop below the minimum of 10 Pa? But if it did, how long did it take for the pressure to recover (to above 10 Pa)?

As you study all the differential pressures, you’ll find three types of cases:

- Above the line: Some DPs remain well above 10 Pa despite door openings/closings. These points are unlikely to cause alarms in the future.

- Borderline: Some DPs dip and come close to the minimum 10 Pa mark, but don’t drop below it. These are borderline cases and may cause alarms in the future. Study how long it takes for the pressure to recover back to the normal level.

- Below the line: There will be a few DPs that go below 10 Pa, which is risky unless the pressure recovers quickly. Study how long it takes for the pressure to recover (see the diagram below).

Once the study is complete, the next step is to put it all together in the form of a report that would be the basis for justifying and setting alarm delays.

Step 4: Write a report

Based on the study, a report needs to be prepared that basically includes:

- Introduction

- Scope

- Observations

- Conclusions

Without going into the details, here are three points about the report:

- Supporting information: The report should stand alone; basically, include all differential pressure trends to support the observations and conclusions.

- Useful insights: A good report is not about dumping impressive loads of information but about deriving useful insights from complex information.

- The observations should clearly state which pressures dipped below 10 Pa and how long was the recovery.

- Which ones came close to 10 Pa but didn’t dip below? How long was their recovery?

- Which ones remained well above the line?

- Recommendation: Based on the recovery times, the conclusions should state the recommended alarm delays.

- The recommended delays must be longer than the actual recovery times to account for normal operations when multiple doors around the facility would be opening simultaneously and other unknowns would come into play. [In one recent case where I was involved, the delay was set to 180 s. In other projects, I have seen delays in the order of 300 s, 600 s, or even 900 s.]

Overall, assessing differential pressure alarm delays is an interesting and satisfying exercise because of the complexity and stakes involved. Never miss an opportunity to be a part of it.

Notes: I have purposefully not included (a) the difference between alerts and alarms, (b) individual room pressure (not differential) fluctuations and recoveries, and (c) door interlocking delays. Eating the elephant in one go is not a good idea.

Finally, leaving you with a point to ponder: For an existing facility where multiple people are already moving around for normal operations what should be the overall window of study: one normal shift (8 hours) or one day (24 hours) or one week?

Atul, really something which should be looked into deeply. We are in the midst of commissioning of HVAC system, will probably share the values one we are done

Thanks for reading. Sure, you’re welcome to share the values.

It’s very useful and must be implemented thing you said. So many Pharma companies didn’t initiated this thing. After reading this it’s seems like this study must be performed.

Thank you very much for sharing …