How to Raise the Quality of HVAC Qualification

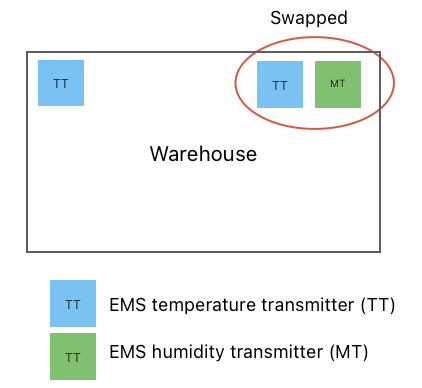

The 3-day HVAC qualification testing of a small warehouse in our fast-paced project had just ended. The testing included recording the warehouse’s temperature (T) and relative humidity (RH) using 29 sensors: 26 portable T & RH loggers and 3 EMS (Environmental Monitoring System) sensors: two (2) temperature transmitters (TTs) and one (1) humidity transmitter (MT).

To everyone’s relief, all temperature and relative humidity trends were within the tolerance (18-23 ºC, <58% RH). With the critical milestone of 72-hour testing behind us, the focus was shifting to executing the HVAC qualification protocol–and eventual handover of the warehouse to the users.

But that sweat sense of progress was short-lived we looked at the EMS trends more closely.

Mystery, mystery

When we kept the two EMS temperature trends side by side, they didn’t show similar characteristics. One trend was how room temperature trends generally behave: a sine wave showing the temperature going up, then down, and then up again. But the other trend was more like a straight line though still within the tolerance. How could the two TTs kept only a few meters apart show different patterns?

But there was something even more puzzling. When we compared one of the EMS temperature trends with the humidity trend, the two didn’t show a correlation. Typically, you would expect the relative humidity (RH) to go down when the temperature increases and vice-versa. But that was not the case. The humidity trend showed a weird pattern, but again, everything was within the tolerance.

Should we proceed with the qualification considering the urgency or dig our heels into the two mysteries surrounding the EMS trends?

The painful lesson

Fortunately, better senses prevailed, and we visited the site to check the three EMS sensors physically. What we saw was shocking!

Comparing the labels, serial numbers, and instrument data sheets of the EMS sensors, we found one of the TTs was labeled as MT, and the MT was labeled as TT. Basically, a TT and MT had been swapped. The TT was reading temperature but was configured to show the output as RH and the MT was reading relative humidity, but its output was configured as temperature. No wonder the trends looked odd.

Next was an expected panic among the project team and confusion about what to do. Could we somehow justify the mistake and still proceed with the qualification or do we repeat the 3-day mapping, which will delay the project by at least a week? After the dust settled, we made the hard but right decision: Fix the wiring of those two EMS instruments and redo the 3-day testing.

We were lucky the EMS sensors mix-up was identified before qualifying and handing over the warehouse to the users. If we had gone ahead with the qualification without looking at the EMS trends critically, millions of dollars of materials would have been stored in this area. And eventually, three or six months later, someone else would have found the problem, resulting in a disaster.

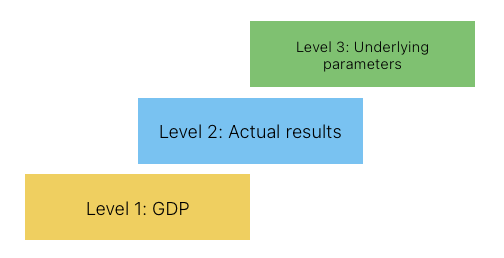

It was an unforgettable lesson that qualifying HVAC systems (or any other systems) is not just about looking at the obvious. In a true sense, quality checks or qualification is a three-step ladder.

Quality checks – three-step ladder

What do people look at while reviewing qualification protocols or doing so-called “quality” checks? Typically, most people focus on the GDP (Good Document Practice) stuff, like date format, blank spaces, N/As, or signatures. They spend considerable time and attention on spotting as many GDP issues as possible. GDP, of course, is one dimension of quality—but far from the real representation of the actual quality of a functioning HVAC system.

Next, moving beyond GDP, people look at the actual results. For example, if the acceptable tolerance of room temperature is 21 ± 1ºC, one would dutifully review if the temperature trends are within the acceptance range. But again, it is also the most obvious part of the quality checks. Consider it as step 2 of the quality ladder.

What about things that are not so obvious, but can affect the quality of the functioning HVAC system? Many HVAC-related disasters (post-qualification), like disrupting pressure alarms, system trips, or humidity spikes, happen because we do not look beyond the obvious and dig slightly deeper, which is step three of the quality ladder.

HVAC qualification – Level 3 checks

If you really care about the quality of HAVC systems, do not get trapped by the GDP quagmire at step 1 or limit the checks to level 2. Look at the qualification results with deeper insights and here are some simple pointers to step up to level 3:

- Review the sequence

- Spot borderline cases

- Compare the results

- Look at key parameters

Review the sequence of testing

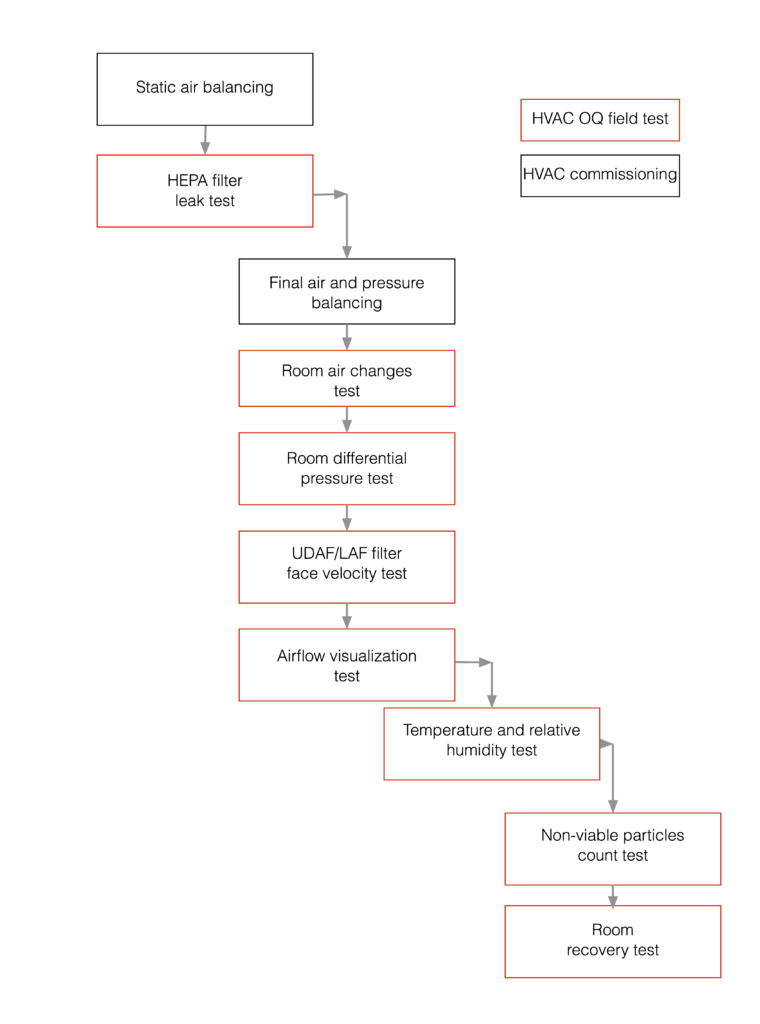

The diagram below shows a typical sequence of HVAC qualification testing and its interface with air balancing. You’ll see that while HEPA filter integrity testing can be done after static air balancing, all other tests require final/dynamic air balancing to be completed.

In the thick stack of HVAC qualification documents, can you assess if the right sequence was followed?

Spot borderline cases

Borderline quality is the quality that can turn sour if the measurements are repeated. For example, if a grade C room requires a minimum of 30 ACH and the test result for this particular room is 30.2 ACH, isn’t this result quite fragile? Or, if the maximum required humidity is 58%, but you see a humidity trend hovering around 57.5%, will it stay there during operations?

The point: Look for borderline cases and try to understand the background to such results.

Compare the results

The warehouse case mentioned at the beginning highlights the importance of comparison–and looking for odd patterns. For example, if an Air Handling Unit with a return air temperature sensor in the main return air duct serves 12 different rooms, more or less you would expect similar temperatures across these rooms. But if you spot some rooms showing rather low temperatures, it calls for a pause to understand the reason. Is it no load? Or, too much air? Or, something else?

Even if all results are acceptable, a little bit of comparison can help to spot the outliers and oddities.

Look at key operating parameters

Here are some key parameter checks that have a bearing on the HVAC qualification results:

- Air changes

- Look for the CAV (Constant Air Volume box) opening percentage. Is it fully open to the max? Or, fully closed? Extremities are not good!

- AHU fan operating frequency: Is the fan operating near or at peak frequency (50/60 Hz)?

- Room pressures

- Look for the VAV (Variable Air Volume box) opening percentage. The healthy range is about 30-80%.

- Room temperatures and relative humidity

- Look at the Temperature Control Valve (TCV) opening percentage. Are any valves fully open or closed?

- Are the chilled water and hot water systems balanced?

Around 2007 when the iPhone had just been launched, one of my friends bought 8 phones at dirt cheap prices from China to gift to all his family members. They looked just like the original phone, but upon use, they discovered the battery drained super fast and the audio and video had a lag. Soon these phones turned into junk.

Indeed, the real quality often lies beyond the obvious as we also painfully learned in our warehouse qualification testing. And going beyond the obvious–level 3–requires a commitment to quality and some extra effort.

Very insightful article written by someone who has plenty of experience and credentials to talk about this art of engineering. Hope this article will be shared and read by as many people as possible and will prevent startup teams falling into this trap. Well done Atul

Thanks, Manuel, for reading it and your kind words. I do not know if my articles make any difference, but I consider them like throwing pebbles in the pond. I hope the ripples reach the right people somewhere at the right time.