How to Avoid Three Classic Pitfalls that Delay Commissioning Right at the Start?

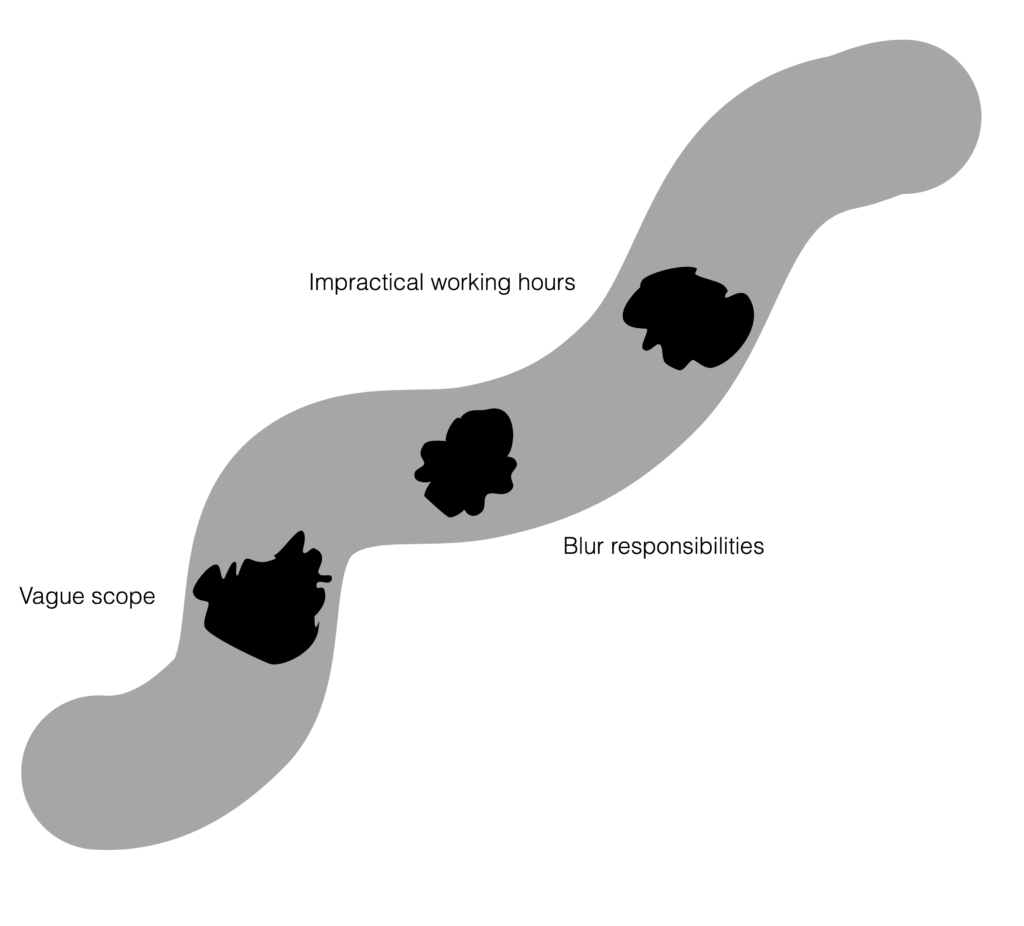

Commissioning is like a patty in a sandwich. It gets squeezed between the fixed project completion deadline and the delays in design and construction upstream. By the time a project progresses to commissioning, it becomes super urgent. The commissioning team always faces intense pressure to get on with it, but that’s where many teams trip into a series of classic pitfalls: disputes about the scope and cost of commissioning with the mechanical or HVAC contractor and its subcontractor (testing and balancing company).

This dispute comes in many shapes and sizes, but in essence, it’s about:

- What

- Who

- When

If a project team can understand these dimensions in advance and plug the gaps, the commissioning can get off to a smoother start.

What (Scope)

The first issue is “what”: the scope of testing and commissioning. Two points here:

- Vague overall scope: The problem often starts with the cookie-cutter specifications issued as part of the mechanical or HVAC tender package. Without properly understanding the scope of testing and commissioning, the mechanical or HVAC contractor assumes some nominal cost for this work—and wins the contract. But when the actual work hits, they realize estimates are way off the reality. And instead of commissioning, people get busy dealing with claims of “additional cost.”

- Vague scope of balancing company: To compound the problem, the HVAC contractor engages a testing and balancing company as a sub-contractor, but again based on an incomplete understanding of the scope. Sometimes, the Purchase Order of the balancing company is just a few words, i.e., air balancing. So when they come on board, their assumption of scope is X, but it turns out the actual scope is 5X+Y+Z. For example, whose scope is it to test the Air Handling Unit (AHU)? The AHU supplier or the testing company or both? Similarly, all pharma projects involve pressure balancing. Who will do that? Who will provide the portable data loggers for the temperature and humidity measurements?

Overall, the roots of the confusion and dispute lie in an imprecise and incomplete understanding of the scope of testing and commissioning, and that too, on all fronts: From people who issue the original specifications to the mechanical/HVAC contractor to the balancing company.

Who (Responsibility)

Blur lines of responsibility: To overcome the scope issue described above and save the cost, many mechanical contractors decide to do what doesn’t work: Instead of engaging a certified testing and balancing company, they try to do this work themselves. This is not a good idea. Not only are they not qualified to do this work, but the test results also have no validity. Testing should be squarely in the scope of a professional and certified testing and balancing company.

When (Timing)

Working hours: The third pitfall involves impractical working hours. Typically, testing and balancing happen over odd hours: late nights and weekends. But often, this part is not accounted for in the original cost.

Overall, due to the loose ends on the three fronts—scope, responsibility and working hours–commissioning starts with a messy dispute, wasting precious attention, time and money.

The solution?

Avoiding the pitfalls

In a nutshell, if you’re managing a project as client or Project Manager or Commissioning Lead, better review the following early in the project:

- First of all, review the testing and commissioning scope defined in the tender package. Can you understand it? Does it describe the actual scope? If not, an amendment or clarification should be issued. This little bit of groundwork at the leadership level makes a huge difference.

- Second, review the scope of the certified testing and balancing company. This is super critical if you want to avoid unnecessary disputes at the last minute. At a very basic level, review whether they have understood their responsibilities and properly included the following basic items:

- Equipment testing (AHUs, fans, CAV, VAV, etc.)

- Static air balancing (also known as rough balancing)

- Final air and pressure balancing (also known as dynamic balancing)

- Temperature and humidity measurements

- Troubleshooting

- Report preparation and submission

- Coordination with other contractors

- All the required instruments

- Team size

- Any specific exclusions, assumptions and support required (ladders, helpers, etc.)

- Finally, always assume that a fair amount of testing and commissioning will happen during odd hours (late night, weekends). Build that into the scope and cost accordingly. Usually, lumpsum cost doesn’t work; most projects end up with manhour cost model for testing and commissioning

Bottomline: Good project management is about looking ahead and avoiding the pitfalls in advance. To ensure commissioning gets off to a smooth start, ensure a clear understanding of the scope, responsibilities and working hours—all across the team. Leaving you with…

Point to ponder: We often worry about “what to do?” Will it help if we also ask, “what not to do?”