Is < 65% Relative Humidity a Safe Bet with Untreated Fresh Air in Singapore?

If there is one issue that often bogs down HVAC designers and building owners in Singapore, it’s relative humidity (RH) in the air-conditioned spaces. Hot and humid, Singapore’s climate demands extra care while designing HVAC systems, or else you end up with unacceptably high RH levels. I learned this lesson–yet again–in a project about two years back.

Our project, a brownfield biopharma site, involved revamping an existing area, about 200 sq m, with a new HVAC system. As the overall scope of the project involved much larger and more critical process areas and cold rooms, this particular area was considered a sideshow, a simple comfort air-condoning job.

Ultimately, however, this seemingly simple HVAC job turned into an RH nightmare, which so often happens in the Singapore climate.

Here is a brief story of this memorable case, from user requirements and design to test results, RH mess and the final solution. And, of course, the lesson learned.

User and local code requirements

The User Requirement Specifications for this area specified 22-24 deg. C temperature and < 65% relative humidity. Nothing fancy—no room pressures, particle counts or special exhausts.

The humidity requirements were in line with the guidance in the local code for air-conditioning: SS 553 (Code of Practice for Air-conditioning and Mechanical Ventilation in Buildings). The code recommends < 65% RH in air-conditioned spaces for all new buildings.

Design and the constraints

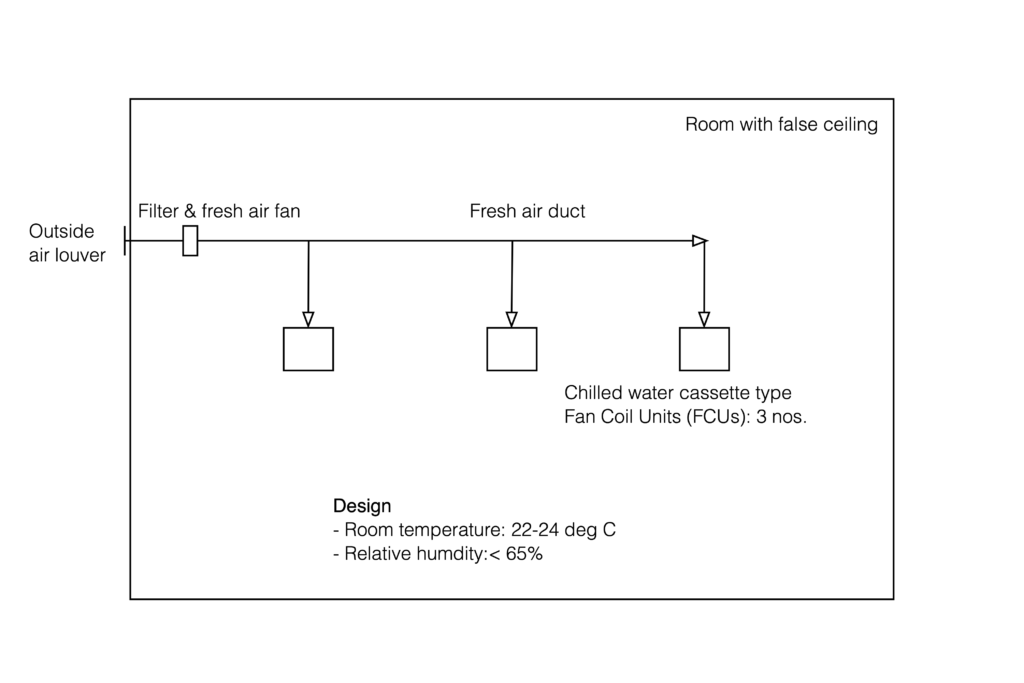

The design of the HVAC system for this room was simple: Three chilled water cassette-type fan coil units (FCUs) with a ducted fresh air supply by a fan from outside. The diagram below shows the design concept.

Why this design? Why not an Air Handling Unit (AHU) that treats the fresh air and then a secondary recirculation type AHU that supplies a mixture of return and fresh air to the room? Why not a dedicated fresh air AHU/FCU to treat fresh air with cassette-type units? Why not ducted fan coil units above the ceiling? Why take untreated fresh air from outside and not tap it from some existing AHU?

Indeed, all these possibilities were explored, but considering the constraints—crowded space above the false ceiling, size of the room and its location, future maintenance challenges, safety and unavailability of hot water—the final design ended up as shown above. The design team did sense the high RH risk, but there was no better design choice.

Test results

Post-commissioning, when I visited the room for the first time, my heart sank. I could feel the stickiness in the air with the portable data loggers displaying RH of around 70%.

The fresh air fan was working and pumping the outside air per the design. The FCUs were operating with two-way chilled water valves that were opening/closing according to the room temperature set point (23 deg. C). And sure enough, untreated or partially treated fresh air was being pumped into the room, causing the high humidity.

The fears of screwing the RH had come true! What could be done?

Improvised solution

Initially, everyone was at a loss, but after a few days of experimentation, it was clear we had to find a way to continuously treat the fresh air without adding new equipment. How could it be done?

Here is what the team did:

- First, the team reviewed the original design fresh air requirements to check if the fresh air quantity could be reduced without causing non-compliance with the local code (SS 553: minimum fresh air for offices: 2.0 CMH/sq. m. | 5.5 L/s/person). Luckily, it was possible to trim it down by 40-50% as the design was a bit liberal.

- Second, we decided to use the central FCU as a fresh air treating unit, which meant all the fresh air came to this unit, and its chilled water valve had to remain open all the time. To keep the valve fully open, its thermostat was set to a very low temperature (17 deg. C).

- Next, the fresh air to the other two FCUs was blocked. As a result, the humidity control now fell on the central FCU while the other two FCUs handled recirculated air, controlling the room temperature.

Did the RH come down?

After the modifications, the humidity dropped to below 65%. Extensive testing confirmed that the improvisation worked, but not without an unintended side effect. Sometimes during early morning hours, when the heat load was almost negligible, the temperature in the room dropped to 21-20 deg. C. The reason was obvious: The central FCU operated with a fully open two-way valve all the time. Although the lower temperature limit was 22 deg. C, this was an acceptable compromise compared to the original high RH problem.

Lesson learned

This episode of high RH yet again reminded all those involved that it’s not safe to commit < 65% unless you’ve a dedicated AHU or FCU to consistently cool and dehumidify fresh air to at least 14 deg. C. Another side lesson was that while designing HVAC systems, if you feel uneasy about a risk building up in the design due to some unavoidable constraints, better to highlight it upfront than give a surprise later.

Every problem that frustrates us teaches something unforgettable and invaluable.

By the way, my role in this project was leading the HVAC from the client side, overlooking the design, construction, commissioning and qualification. Finally, leaving you with…

Point to ponder: If you’ve three cassette-type FCUs serving a room, where would you keep the three thermostats controlling these units? In one location or distributed across the room?