What can be Leveraged from Commissioning to Operational Qualification (OQ)?

Leveraging is a buzzword you’ll find floating around as soon as the qualification team comes on board a project. Q team’s first task is to formulate a “qualification strategy” for the project, including a critical piece called “leveraging.”

Essentially, leveraging is asking three questions:

- What’s in?

- What’s out?

- What’s in from out?

What’s in?

Which HVAC tests fall under the scope of HVAC Operational Qualification (OQ)? These tests would be carried out during OQ. [Example: Non-viable particle count test]

What’s out?

Which HVAC tests are out of OQ? These tests could be done at the vendor’s end or during commissioning and will not be used to support OQ. [Example: Air Handling Unit testing]

What’s in from out?

Which tests can be “leveraged” from outside OQ? These tests are required for OQ but would be done before OQ (e.g., during commissioning) and “leveraged” to qualification. [Example: Room air changes]

In simple terms, leveraging a test means you don’t repeat the test; use the test results from commissioning in your qualification protocol.

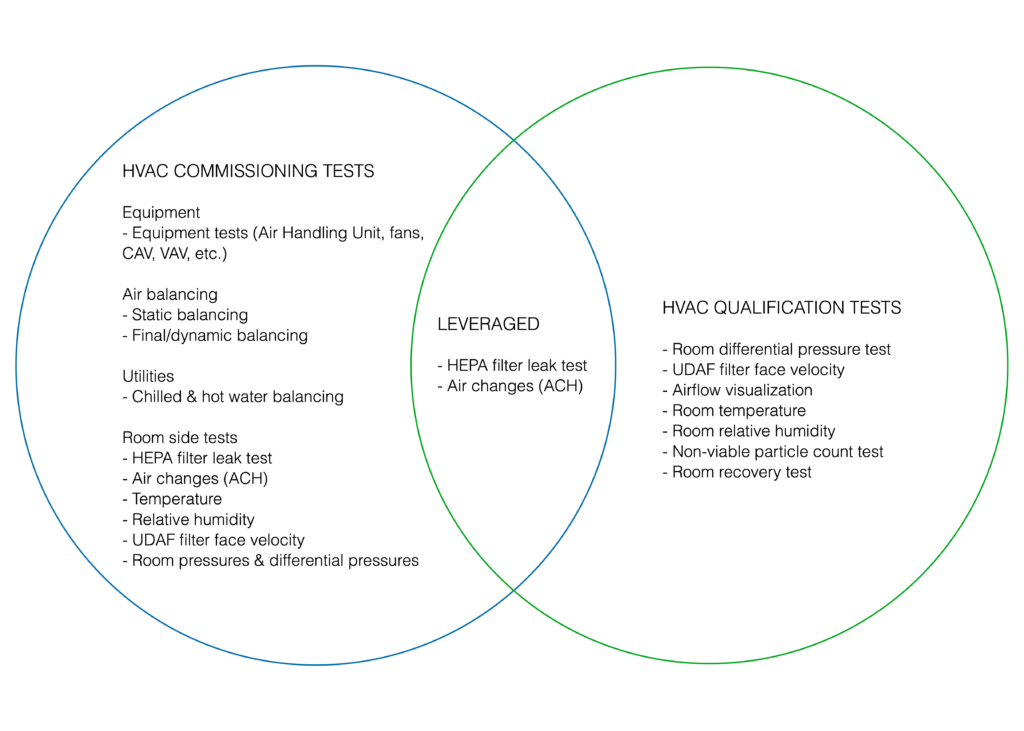

The diagram below shows the answers to the above three questions for a typical HVAC pharma project that involves standard cleanrooms with pressure cascade and a few UDAFs.

Leveraging – risks and rewards

Leveraging saves precious time and cost by not repeating the tests that are already done before qualification. But at the same time, it adds to the risk, and that’s why not all commissioning tests should be leveraged.

Typically, the following HVAC tests are leveraged from commissioning:

- Air changes (ACH)

- HEPA filter leak test

I have been in a project where the ACH test was also not leveraged, and a separate team was assigned to remeasure air changes during qualification. But that was more than ten years back. Nowadays, with tight project schedules, clients settle to leverage ACH from the final Air Balancing Report generated during the commissioning.

Why can’t we also leverage the temperature, relative humidity (RH) and pressures? After all, these items would be tested in commissioning as well.

Well, here comes the element of judgment about leveraging. If you overdo it, the risk increases dramatically. During regulatory audits, unnecessary leveraging can be challenging to defend. Also, you don’t want to be in a situation where you leverage the commissioning data and then fail in Performance Qualification (PQ). Leveraging strategy needs to be carefully planned without compromising the quality and reliability of qualification. Typically, room temperatures, humidity and pressures are remeasured during qualification–and that’s a wise move.

Finally, the scope and rationale of leveraging should be clearly defined in the Validation Master Plan and HVAC qualification protocols.

Hi Atul, Good Article for the art of leveraging. I would add that if any CPP (e.g. room pressure trends) can be obtained easily, I would repeat the test from from commissioning. This will prove that the HVAC is working consistently and reproducibly. Let me know what do you think?

Regards,

Dickson

Dickson, in my view, both individual room pressures and room differential pressures should be thoroughly tested during commissioning. But qualification is about the room differential pressures only. Anything “not necessary” included in the qualification has a lifecycle cost: Users may need to keep monitoring and validating it for all years to come.

Overall, there are two schools of thought: Some people feel safer when more things are included under qualification. For example, some argue to include the AHU, ducting, etc. under qualification as well. The other school belongs to those who want to minimize the exposure during qualification and include only what is really needed. I lean toward the latter with a caveat: Do excellent commissioning so people don’t have this urge to push things from commissioning to qualification.