How to Systematically Walk-down a System?

Mechanical Completion (MC) marks a significant milestone in any project when the construction team hands over a system, such as an Air Handling Unit system, to the commissioning team. For the construction team, it’s a moment of relief. For the commissioning team, it’s the start of a hectic testing and commissioning phase. However, one critical activity must be completed before the handover takes place: the final system walk-down.

The purpose of the walk-down is to enable all key stakeholders to take a final look at the installed system, identify any gaps, and determine whether to accept the system as mechanically complete. The walk-down is attended by the construction team, commissioning team, client, and safety personnel.

One would imagine the final walk-down to be a systematic activity that brings everyone together to inspect the installation and share constructive suggestions for improvements. In practice, however, it often turns into a chaotic formality that results in superficial comments, confusion, and even crazy outcomes.

Typical walk-down

Typical walk-down starts with 10-12 people arriving on site and starting to look at the installation. Almost no one comes prepared or understands the system completely. Everyone knows only a little piece of it. No one briefs the team about the overall system. Different people start looking at different things, and giving comments about what’s not complete or right. Someone talks about piping only to be injected by someone else who wants to highlight messy electrical wiring. Out of anxiety to add value, sometimes, people throw in crazy suggestions that can’t be implemented. In the end, everything gets mixed up, and the most common comments from these walk-downs are about trivial stuff like labels and tags, not the most critical things to worry about.

To everyone’s relief, the activity gets over after an hour or so, but people don’t return with confidence. There is always a sense that it was a mere formality, and some things might have been missed. In short, the “final system walk-down” gets ticked in project milestones, but it doesn’t add as much value to the project as it could.

Tips for a systematic high-quality walk-down

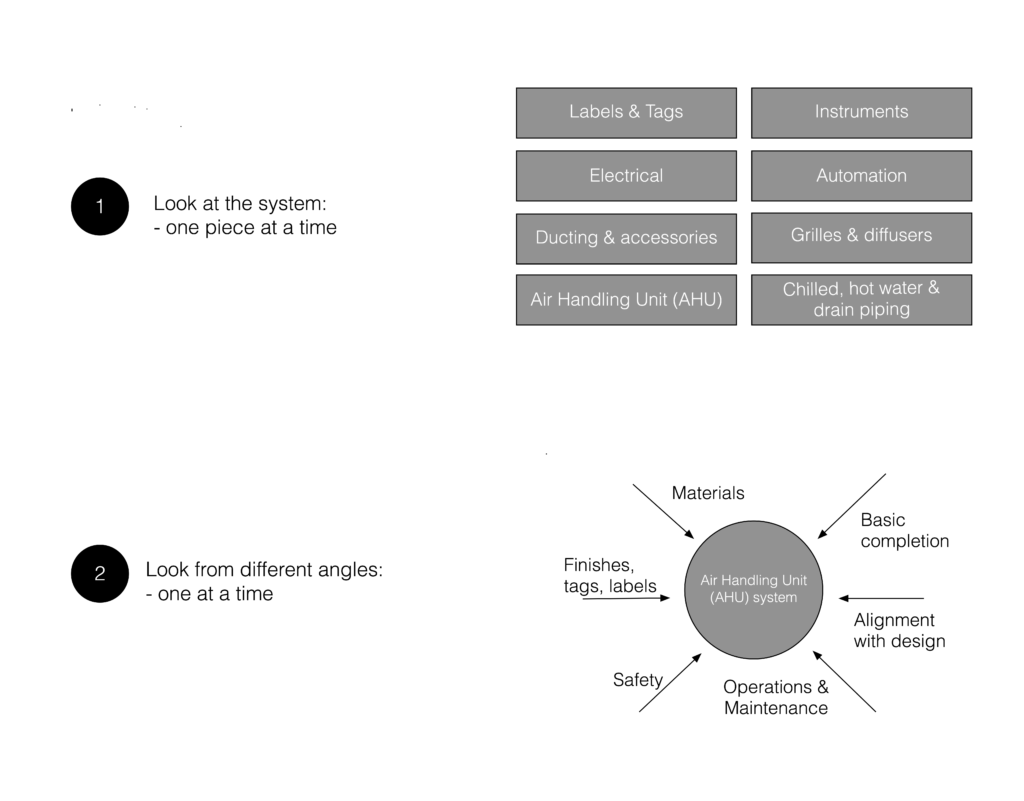

The diagram below shows two keys to turning walk-down into a systematic activity.

To have a walk-down that brings everyone together and uses collective knowledge and attention to enhance the quality of the system, consider the following:

- Documents: Make sure the latest versions of all relevant drawings and documents are available during the walk-down.

- Lead: The HVAC lead engineer from the construction team or Project Engineer should lead the walk-down.

- Presence: Ensure that all relevant stakeholders are present, including the main contractor, sub-contractors for the AHU, ducting, piping, electrical and automation, client’s SME, commissioning lead, and safety representative.

- Brief: Present the drawing and give a short overview of the key components and scope of the system.

- One piece at a time: Guide people to examine one item at a time (AHU, ducting, piping, etc.) and mark it/highlight on the design drawing.

- One angle at a time: Consider each item from different angles, one at a time, focusing on basic completion, alignment with design, operations and maintenance, safety, finishes, tags, and labels, and materials.

- Conclusion: Once the walk-down is over, have a short standing meeting to read aloud all the comments/punch list items and categorize them (Cat. 1, 2, or 3). Finally, have all key stakeholders sign off on the walk-down completion form.

It may not be possible to adhere to the above list 100% in a typical project setting, but aspiring to do it perfectly can raise the effectiveness and quality of your walk-downs. The final system walk-down offers an opportunity for the construction team to showcase all the hard work they have been doing and earn clients’ confidence. Don’t let it pass!

Remember two key points:

- A system is simply a sum of its parts; look at it part by part.

- When multiple angles are involved, look at it from one angle at a time.