Why is a Well-Written HVAC Commissioning Protocol a Game Changer?

Regarding HVAC C&Q (commissioning and qualification), everyone understands that the second part – Q (qualification) requires detailed qualification test protocols. Tremendous effort goes into writing, executing, and approving these test protocols (DQ, IQ, and OQ) that serve as the “proof of the quality” during regulatory audits. But what about the first part of C&Q – C (commissioning)? Does it also make sense to create commissioning protocols that neatly and systemically capture all the commissioning test results?

Why HVAC commissioning protocol matters

Hard to digest, but HVAC commissioning/testing follows the following maxims:

- If you write a test, it will happen. If you don’t, it may be missed out.

- If you want test A to happen before test B but do not define it in some written document, the sequence will likely go haywire.

- The way you write a test, that’s the way it will happen. If you write it vaguely or do not define the acceptance criteria properly, vague/inaccurate results will be recorded.

In short, the document drives the testing, and the quality of testing directly follows the quality of the commissioning document.

If an HVAC commissioning team creates test protocols that correctly define the required tests, sequence, and precise acceptance criteria, that’s a massive step toward ensuring the quality of commissioning. The Converse is true as well: If the HVAC commissioning documents are missing or incomplete, or vague, chances are bright that commissioning will be a shoddy affair.

The worst case I have seen is a project where due to lack of proper documentation, the commissioning was declared as “complete” pre-maturely, only to lead to massive failures during qualification—and huge rework.

Overall, preparing high-quality HVAC commissioning protocols is an investment that saves a project from unnecessary rework, mess, delays, and cost escalations.

So, what goes into an HAVC commissioning protocol?

Anatomy of HVAC commissioning protocol

Before we go into the details, let’s first reconnect with the purpose of an HVAC commissioning protocol: It’s one document that captures all the relevant checks and test results of a single HVAC system, from AHU testing to air changes to pressures to automation checks. If anyone picks up this document, he/she should be able to review all the commissioning records for an HVAC system. If a project has 12 HVAC systems, 12 such protocols are needed.

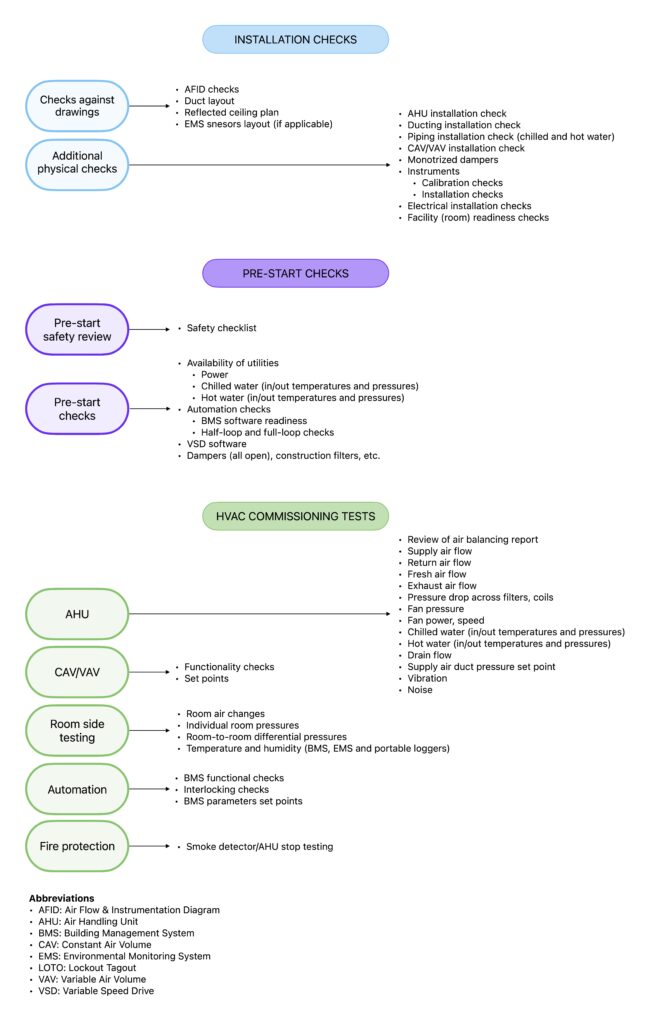

What goes into the commissioning protocol? The diagram below shows the basic architecture of an HVAC commissioning test protocol for a simple HVAC system (Air Handling Unit, ductwork, CAVs/VAVs, etc.). This can be modified to suit specific systems, but the basics remain the same: It includes a section to confirm installation checks, a section on pre-start checks, and the last section on actual field commissioning tests.

The difference between hotch-potch and robust HVAC commissioning lies in the existence and quality of the HVAC commissioning protocols. It’s like first committing on paper what will be tested, in what sequence, and against which acceptance criteria. This pre-commitment is truly a game-changer!

Finally, leaving you with a point to ponder: Why is it necessary to include installation checks in the commissioning document?