What if You’re Stuck on a Flight With Nothing to Read Except ISO 14644

Hope it never happens in reality but only in the imagination: It’s a long-haul budget flight with no onboard entertainment like movies, magazines, or newspapers. You’re desperately trying to sleep but the more you try, the more you miss it. Seeing your ordeal, the flight attendant comes and shares a secret medicine to put you to sleep right away: ISO 14644 standards. She asserts that anyone who reads these standards for even 5-7 minutes, goes to deep sleep without fail.

Being from the pharma industry, you understand the importance of ISO 14644 standards–and of course, you also know the importance of good sleep on a long-haul flight. So you reluctantly nod to the attendant.

Here is what she brings…

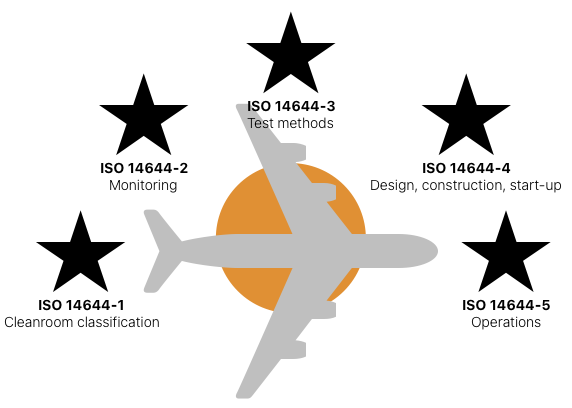

Looking at the stack of five standards, you’re already feeling slightly sleepy, but decide to take the full medicine and start opening them one by one. You tell yourself that at the most you’ll give five minutes to each standard, which means you’ll scan and extract anything useful from an HVAC point of view.

ISO14644-1: Cleanroom classification

Browsing this standard, you quickly figure out that basically it’s about three things:

- Cleanroom classifications

- Number of sample locations

- How to do particle count measurements (you ignore this part and dive deeper into the other two)

ISO Classes of air cleanliness by particle concentration

The following is the most practical part of a big table in ISO.

| ISO Number | Max. allowable particles ≥ 0.5 µm/m3 | Max. allowable particles ≥ 5.0 µm/m3 |

| 5 | 3,520 | N/A |

| 6 | 35,200 | 293 |

| 7 | 352,000 | 2,930 |

| 8 | 3,520,000 | 29,300 |

Are these numbers “at rest” or “in operations” mode? Although the table doesn’t say and leaves it open for the customers to decide, practically, these numbers belong to the “in operation” state.

Number of sampling locations

ISO 14644-1 also includes a very useful table to give you the minimum number of sample locations for the particle counting test.

| Area of cleanroom (m2) less than or equal to (A) | Minimum number of sampling locations to be tested (NL) |

| 2 | 1 |

| 4 | 2 |

| 6 | 6 |

| … | … |

| 1000 | 27 |

At this stage, you’re slightly more awake, so you decide to move to the next standard.

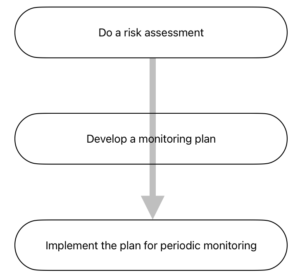

ISO 14644-2: Monitoring

As you browse through this one, you quickly realize it’s meant for those who operate cleanrooms: It provides detailed guidance on monitoring particle concentrations in existing cleanrooms to ensure continued classification.

It suggests a simple 3-step process to develop a monitoring plan as shown below:

The plan would include parameters to be monitored, methods, acceptance criteria, calibration of instruments, frequency, and data management. The standard recommends the following tests: Particle monitoring, differential pressure, and airflow velocity or volume.

You feel good about the face-to-face meeting with this second standard but still not feeling sleepy enough, decide to move to the next one.

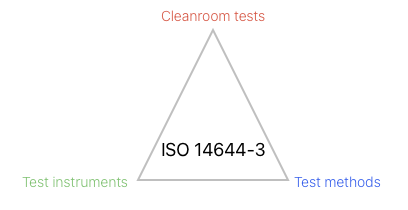

ISO 14644-3: Test methods

This one looks useful for those who build cleanrooms, test cleanrooms, or own new cleanrooms. Looking at 14644-3, you find that basically it’s about just three things:

So what are the tests that you should do for certifying a cleanroom? Besides the particle count tests as per ISO 14644-1 (mentioned earlier), the following tests:

- Airflow rate & Air Changes

- Airflow visualization

- Pressure difference

- Temperature

- Humidity

- Filter leak test

- Containment leak test

- Recovery test

The standard provides good details on each test and the instruments.

Since you’re feeling slightly sleepy but still not confident of falling asleep, you decide to move to the next one.

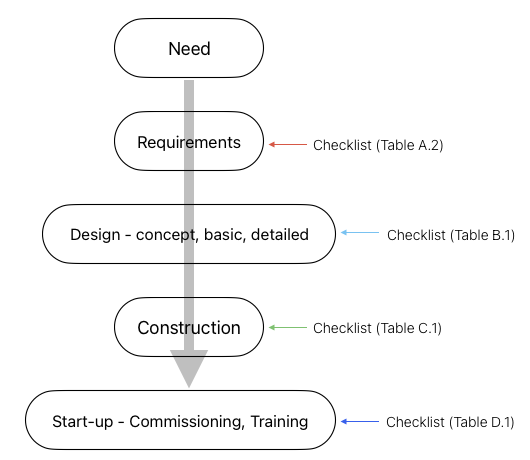

ISO 14644-4: Design, construction and start-up

Looking at this standard, you just wish that project teams who build cleanrooms would follow it. What’s so special about this one?

This standard lays down a systematic path for building cleanrooms, from well-rounded user requirements to design to construction to start-up. It provides useful information on pressure cascades, airflow patterns, and contamination control. On the practical side, it provides excellent checklists that project teams can use at every stage of the project to ensure all requirements are covered.

At this stage, you’re indeed feeling quite sleepy, but since only one more is left, you decide to complete the full dose of ISOs for a deep sleep later.

ISO 14644-5: Operations

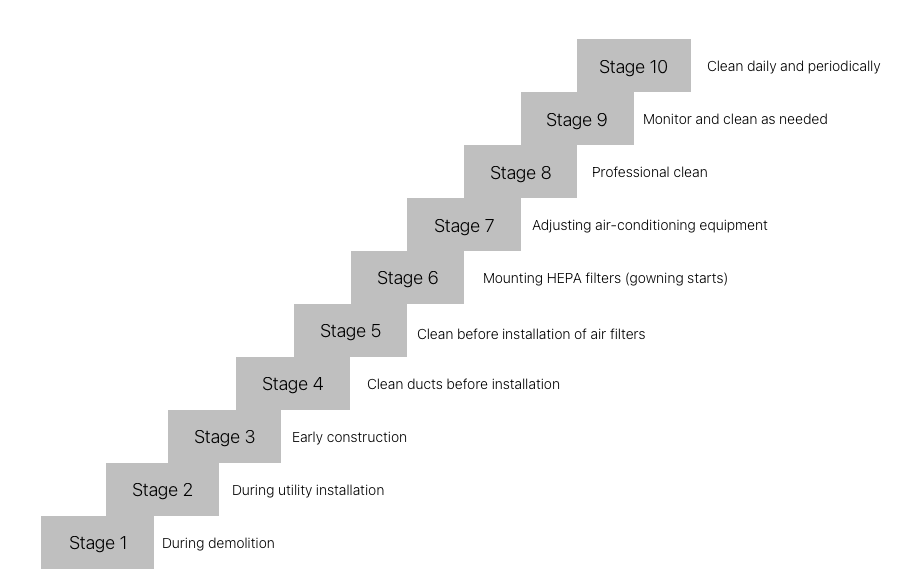

As you open this last standard, you realize it’s more about operating cleanrooms in terms of systems, gowning, personnel, equipment, and cleaning requirements–useful for those who operate cleanrooms. It doesn’t include any specific HVAC-related stuff except the 10-step cleaning process during project construction.

At this stage, as the flight attendant had promised, you’re feeling very sleepy. In fact, so sleepy that all five ISOs fall off your lap and you’re enjoying a deep zzzzz…

Upcoming…

I will be offering a training program titled “HVAC for Biopharma Professionals” next week. Check it out here.

Good read, easy summary guide for busy professional to know the difference between part 1 to 5

Easy for understanding sir. Keep going